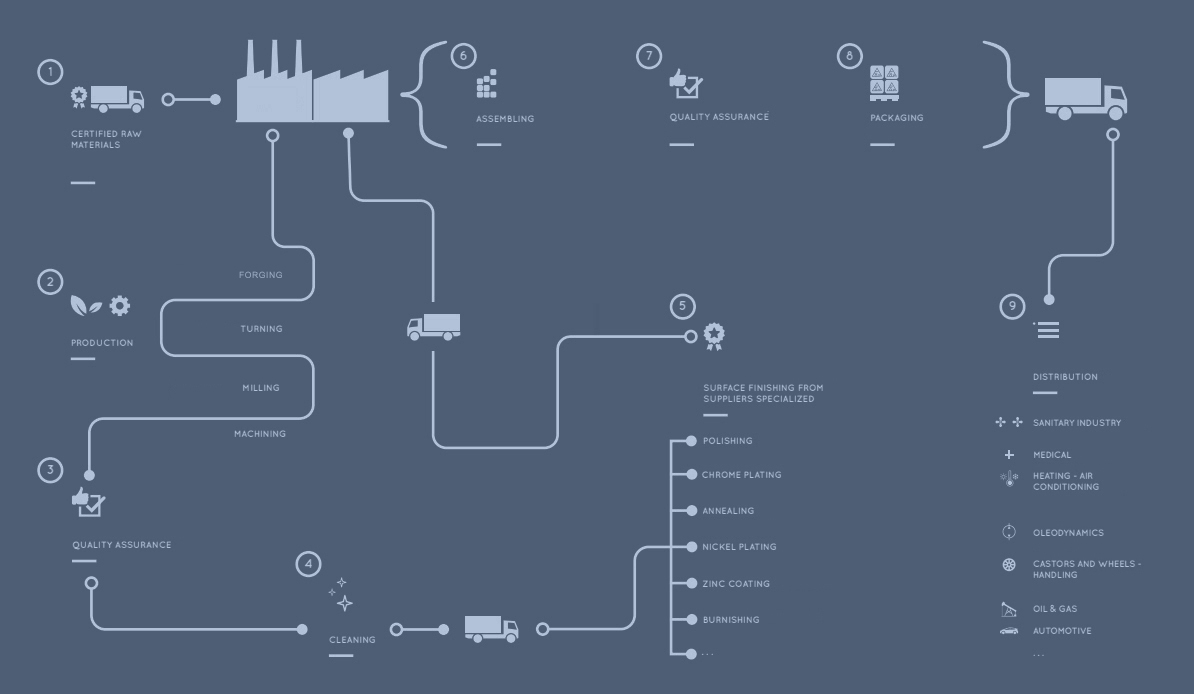

Manufacturing Process

Your product will be improved to obtain a quality item at a competitive price.

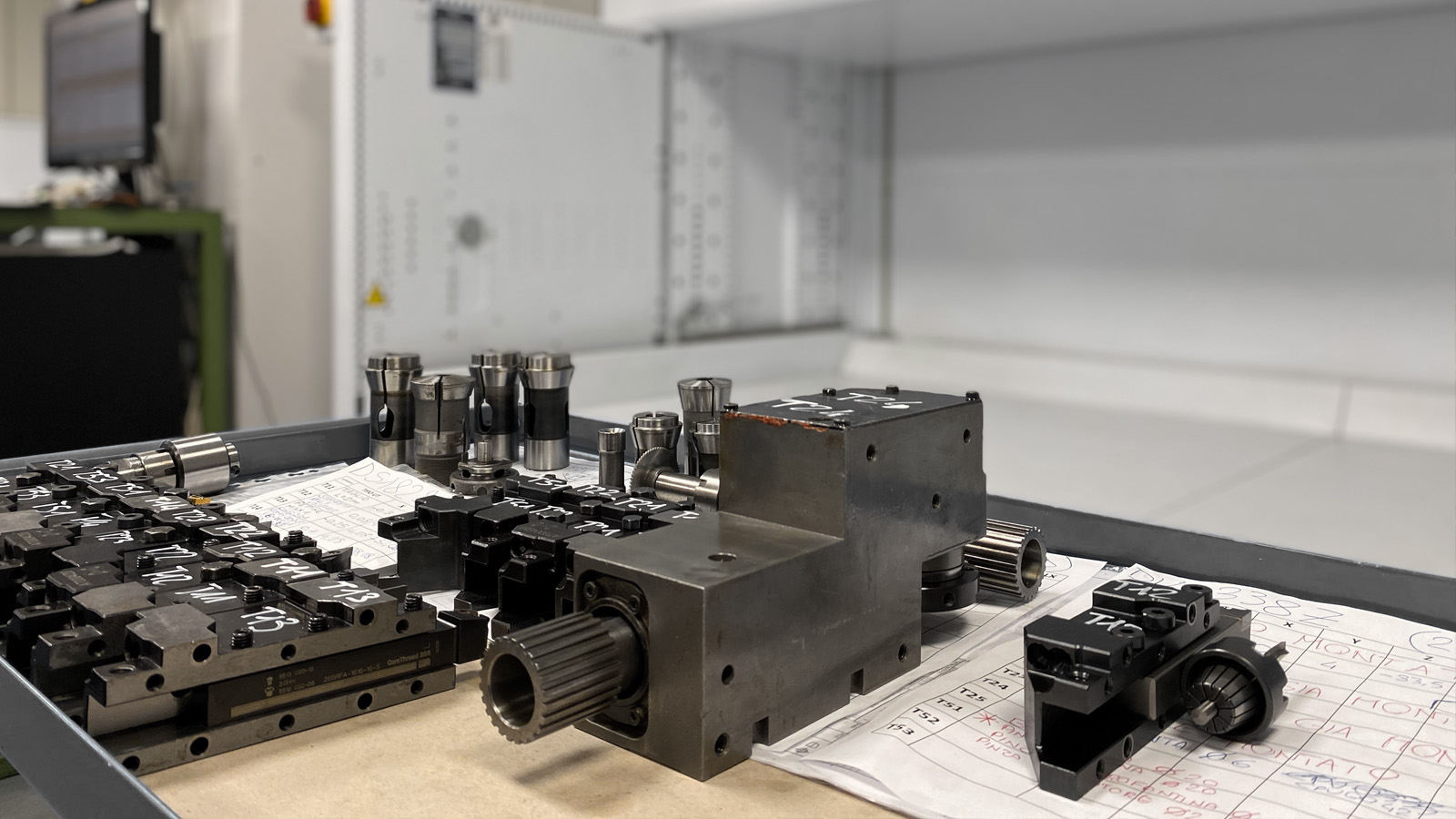

In order to make the production process faster and more optimised, each production department of Tulsi International has its own tools.

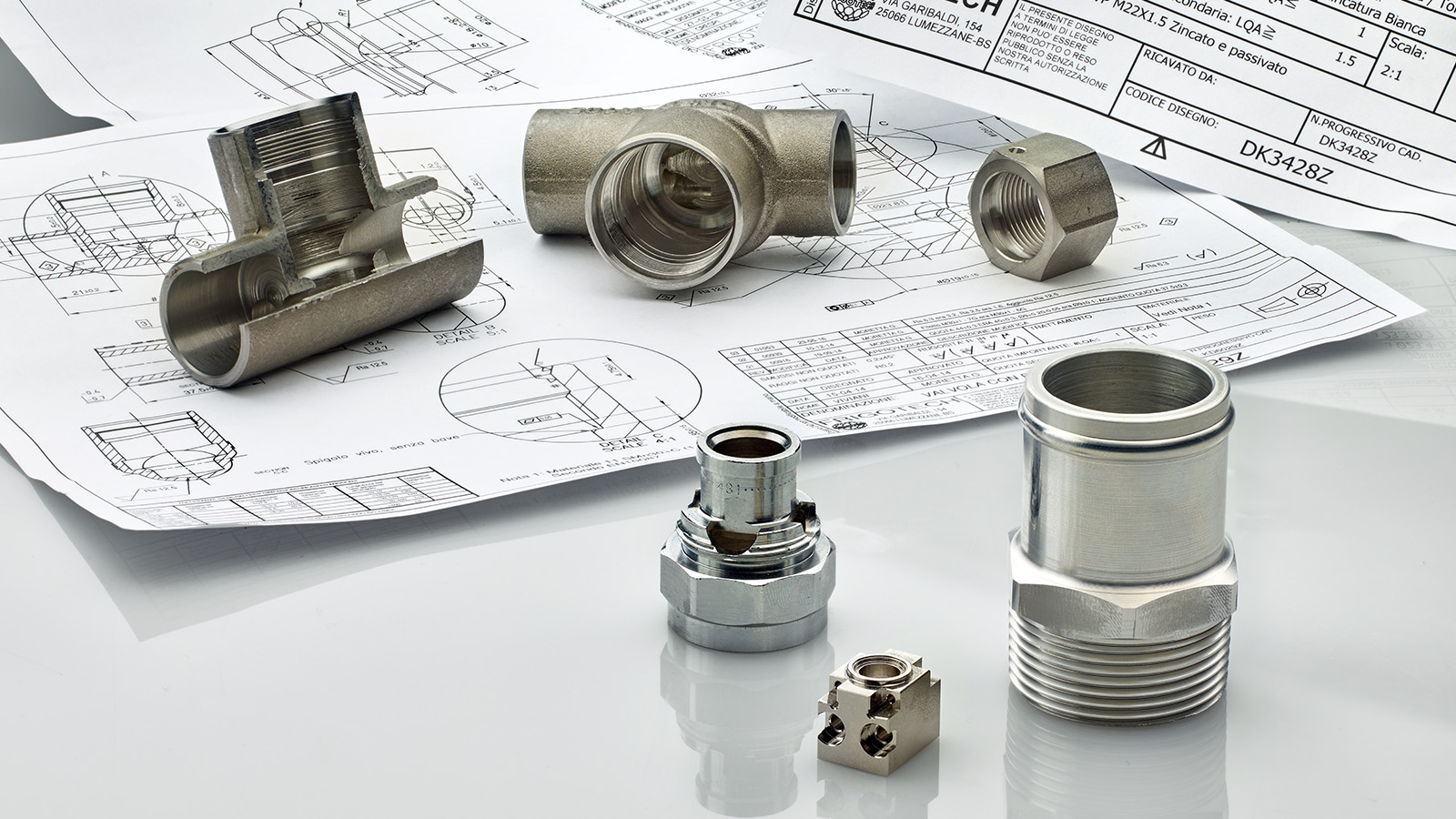

Forging is a metal shaping process where heated metal is compressed into shape using controlled force. The result? Higher strength, better grain flow, and long-term reliability compared to cast or machined-only parts.

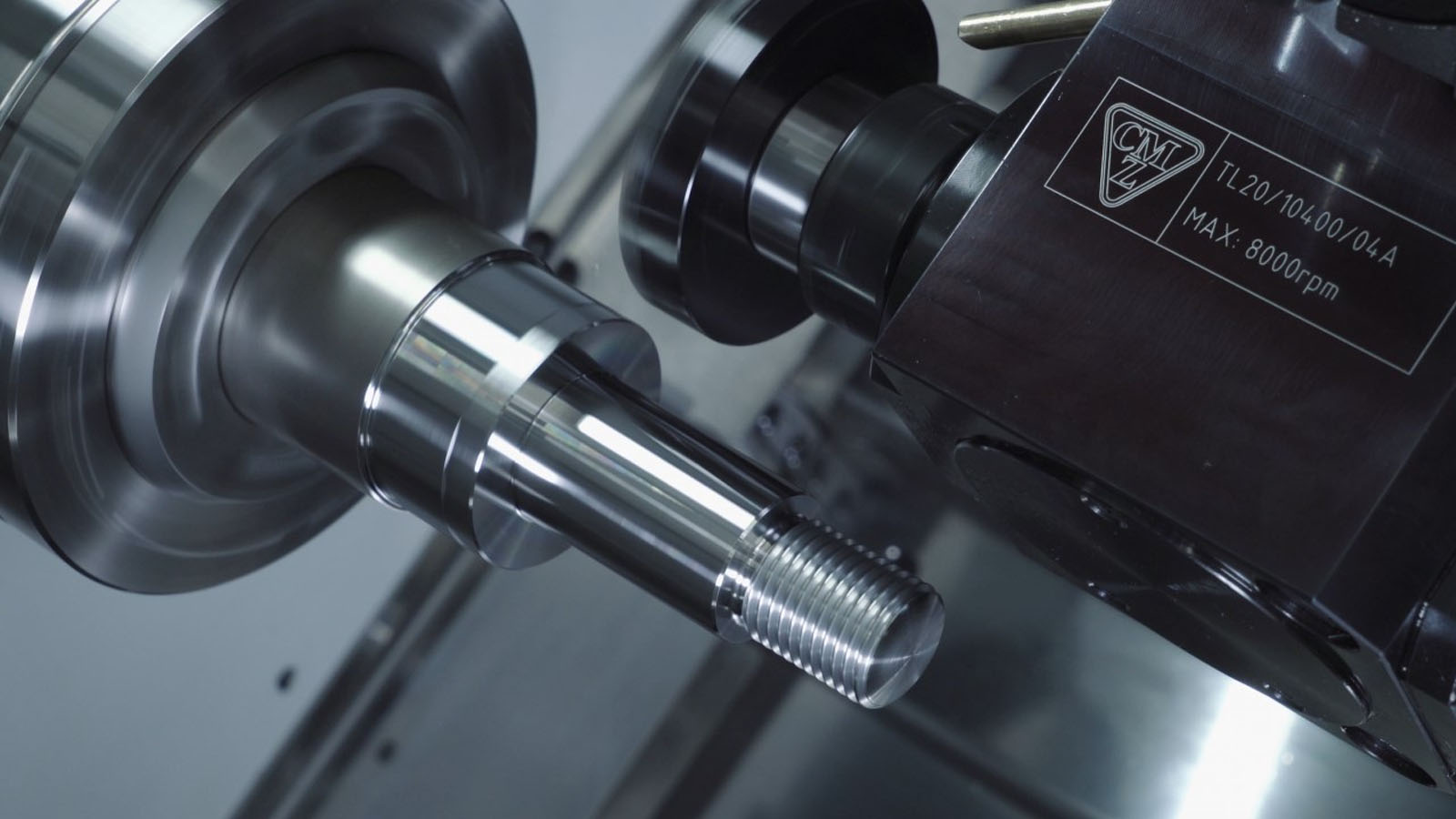

Turning processing is our core business. We can rely on a wide range of equipment to process the most diverse materials, always ensuring top product quality and timely delivery. Processed bar dimensions: 3mm to 200 mm Piece.

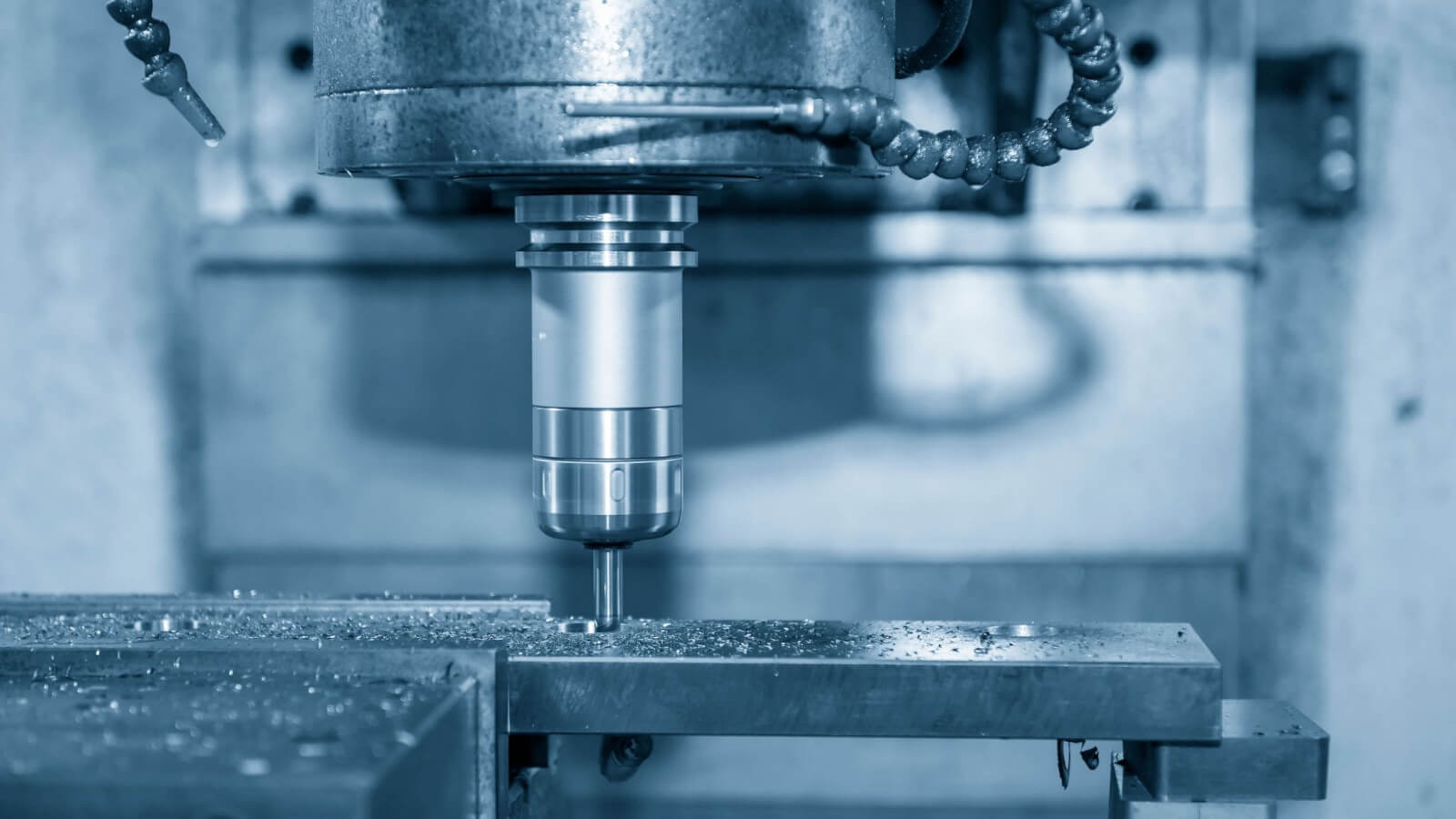

Milling processing is performed with ISO40 and ISO50 horizontal and vertical machining centres, equipped with high pressure for machining even tough materials. We can perform re-machining of moulded and/or die-cast products, or machining of square, rectangle and other profile shapes.

Poly turning is an advanced CNC turning process where multiple operations are performed in a single setup. It delivers high accuracy, faster cycle times, and consistent quality—ideal for complex metal components.

State-of-the-art control equipment and machinery and the great professionalism and experience of the staff aim to guarantee full compliance with the requirements of the processed products, promptly identifying any problems and taking appropriate corrective action.

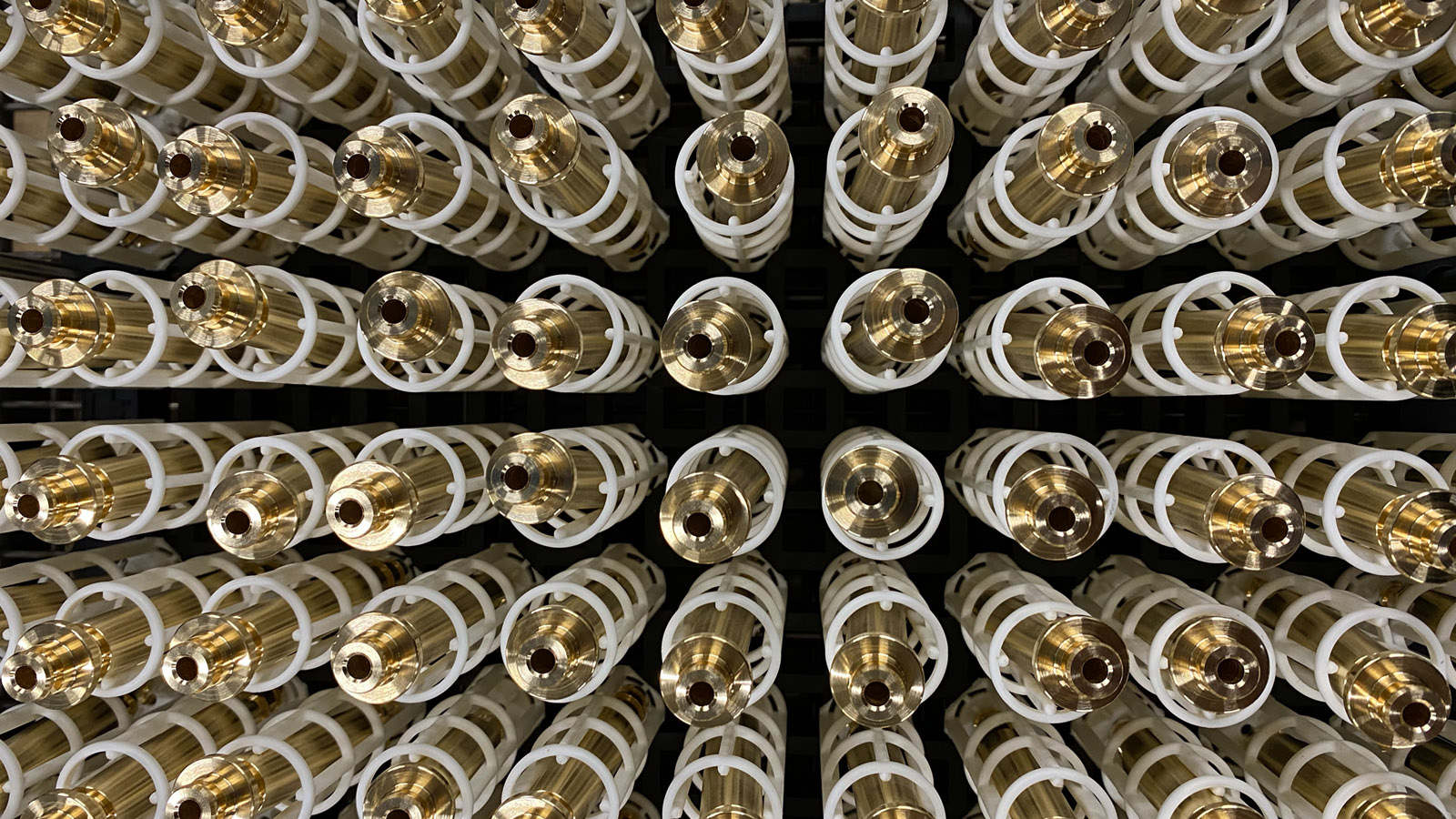

In addition to the supply of any type of carefully packaged part, Tulsi International also offers the assembly, testing and checking of products to the required specifications.

A service adapted to every need. Tulsi International offers its customers the possibility of agreeing on minimum stocks that are always available and on storage of delivery batches that are always ready to be dispatched.

Quality Process